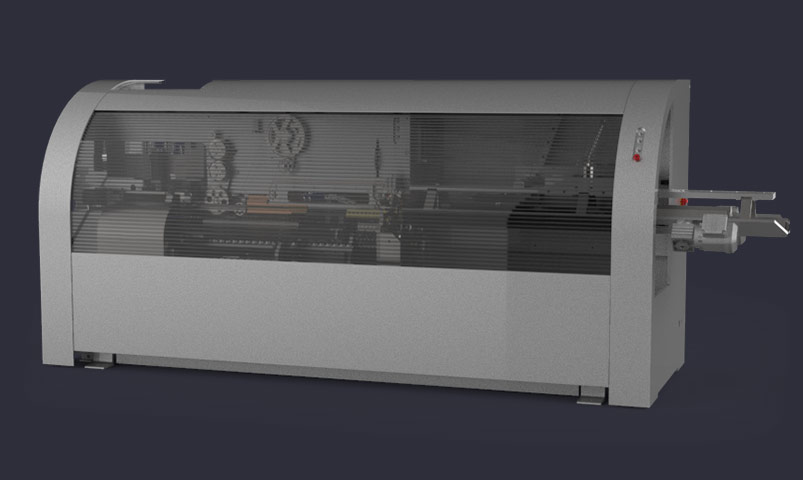

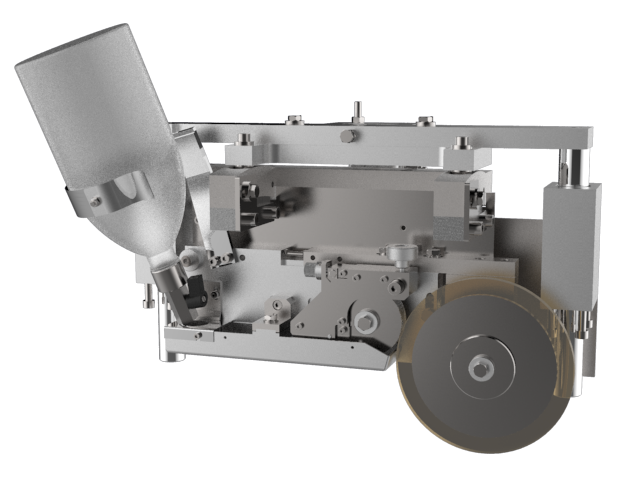

Automated can body height change – 2 minutes and you are ready for a new production run.

In 30 minutes you’re able to perform a complete diameter & height change – an unbeaten world record for medium- and high-speed welders!

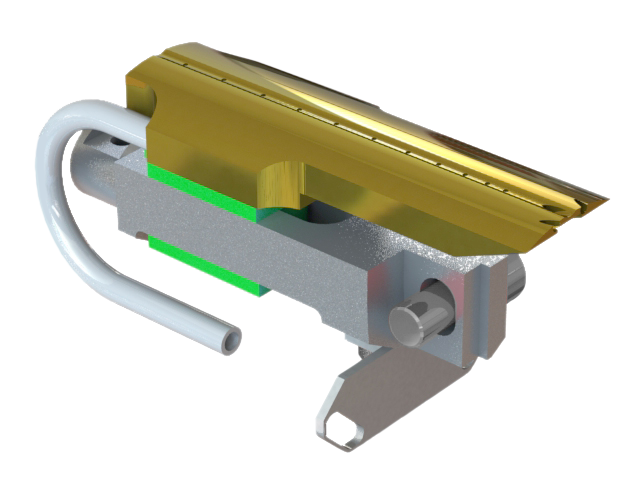

To prevent that the coating breaks off the seam which could contaminate the can-content.

For a silver coloured seam and to prevent that the seam coating breaks off the seam

Wired operators panel including iPad Pro 12.9"

Wireless 9.7" HMI in a multifunctional aluminium housing

With Infrared- and Acceleration- sensors, including can ejection system

Including software, sensor and eject cylinder to reject cans which are detected as "faulty" by the Pacemaker™

NOTE: Not required when Qualimaker2™ is chosen

Signal and status lamp (green, yellow, red)

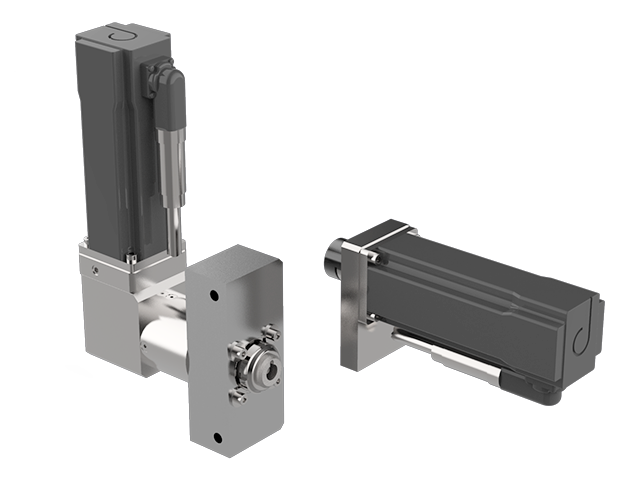

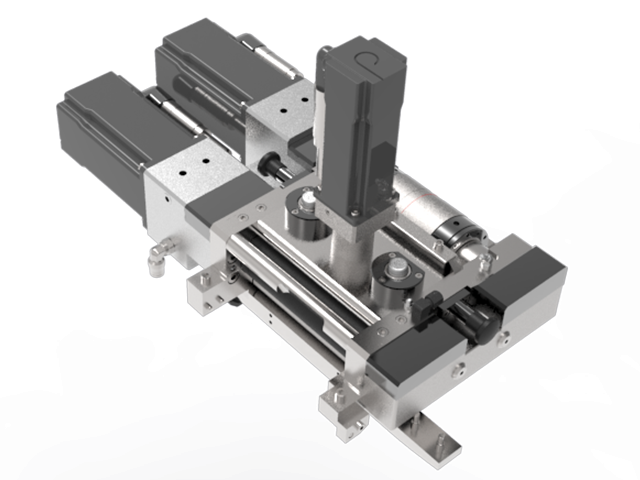

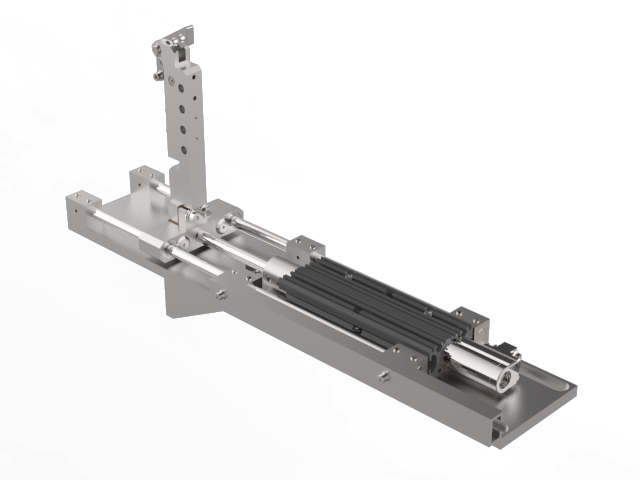

High performance rollformer for max. canbody - height of 120 mm, synchronized blank transfer and soft impact feature. Delivered without servomotors.

Universal rollformer for max. canbody - height of 320 mm, synchronized blank transfer and soft impact feature. Delivered without servomotors.

With integrated scoring station for max. canbody - height of 120 mm (max 60 mm single-can-height), with soft impact feature. Delivered without servomotors.

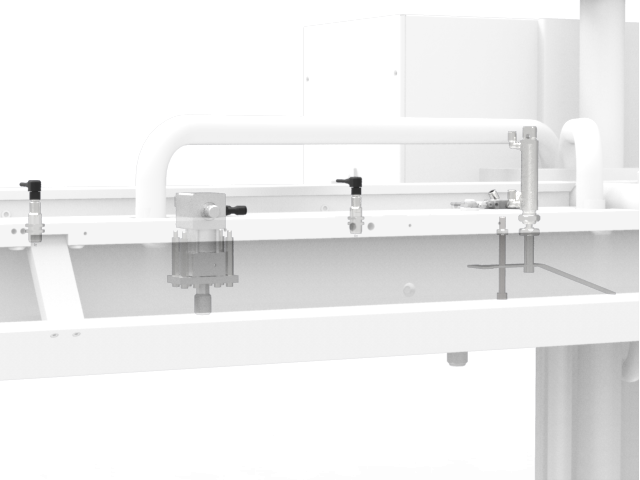

Chiller with bypass circuit, including cooling additive and water filter system. Needed for canbody production, but could be organized locally according to Can Man's specifications

Lacquer supply by inverted bottle

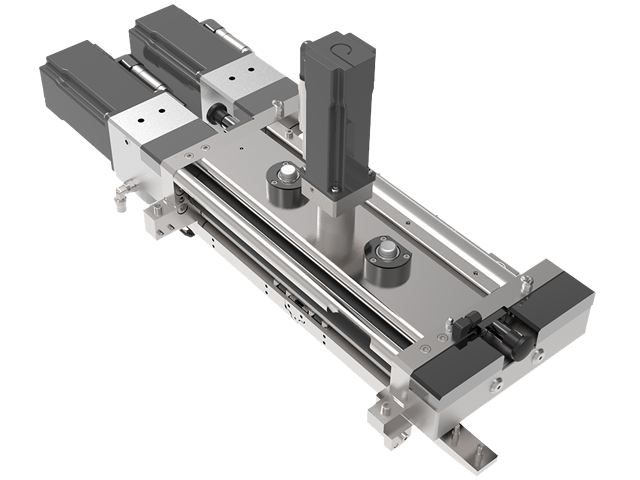

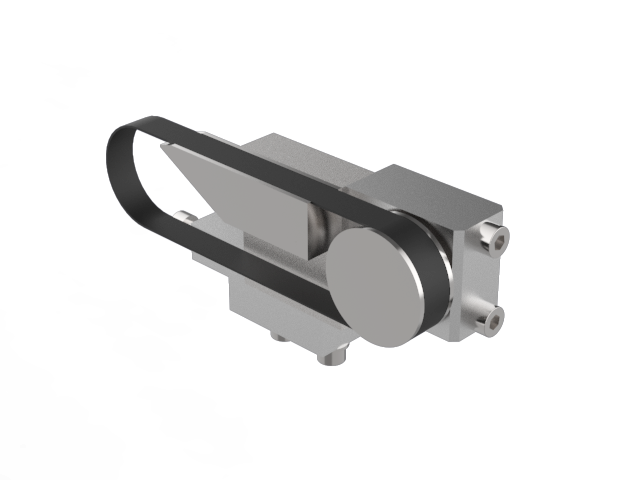

This supporting conveyor grants a smooth transportation of short canbodies, which is particularly important for precise weldmonitor measurements.

The driven bottom diaboloroll prevents any „tumbling“ of the canbody at the entry into the calibration crown and during the welding process.

The supporting conveyor is driven by a servo-motor and is automatically synchronized with the welding speed. The drive system as such, includes its mounting base, cabling and electronics.

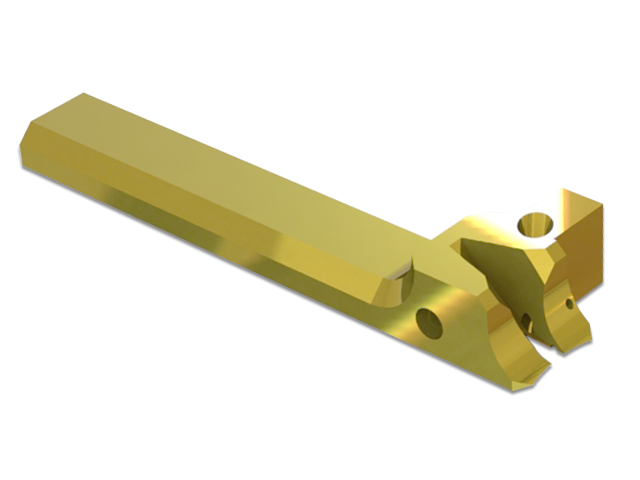

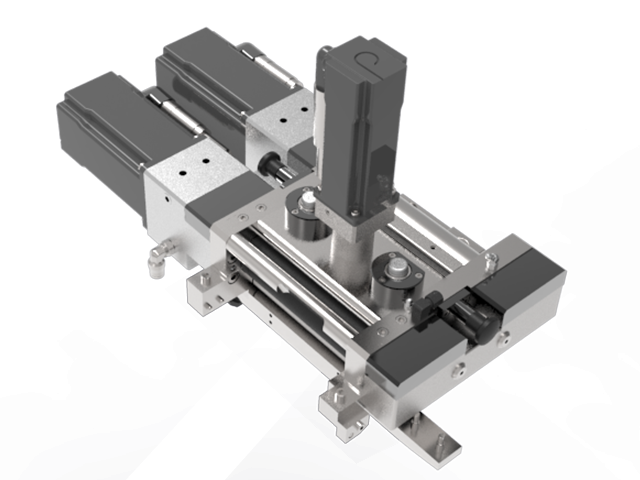

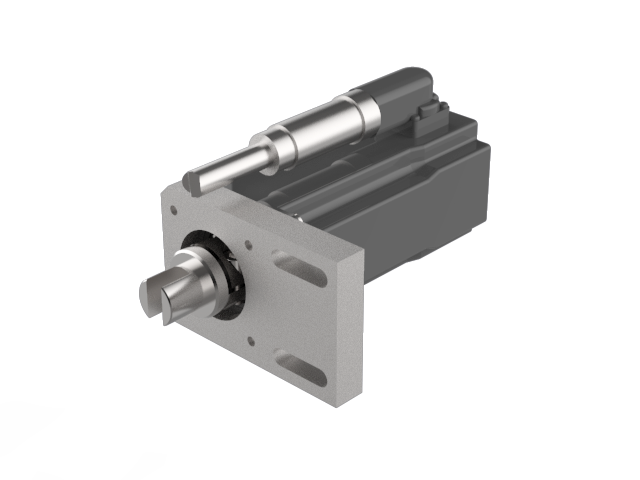

For canbodies which are shorter in height than in their diameter (i.e. ø 99 x h 80 mm) a third push finger is required for insertion of the „ring - like“ canbody into the calibration crown. The speed limit of this device is at 300 1/min at this moment, but will be increased to 400 1/min soon (news will follow).

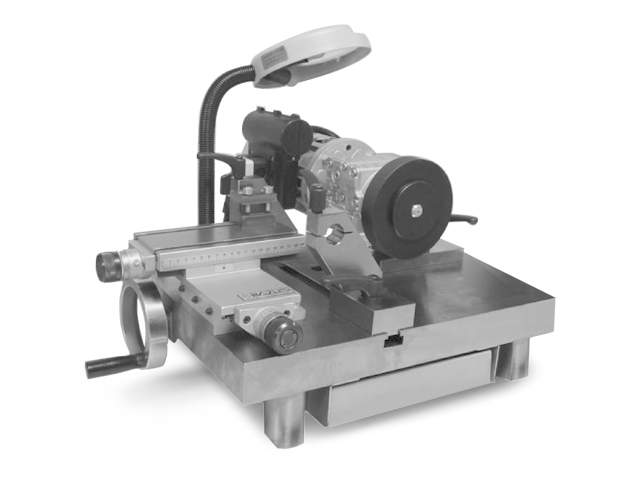

Recommended for a precise grinding / profiling of welding rollers

2 copper wire ends can be welded if copper wire coil needs to be exchanged; 1 die for 1 or 2 copper wire diameter (to be specified) included

For "offline" control of blanks, portable and made with first quality materials for highest measuring precision

For "offline" control of blanks, made with first quality materials for highest measuring precision

For "offline" control of blanks or sheets up to a length of 1000 mm, made with first quality materials for highest measuring precision

Measuring unit with data interface for inside diameter, including tool for 1 canbody diameter; available for ø range of 52 - 127 mm

Test of the entire seam including the beginning and end of the can.

Easy spring back (hardness) testing of tinplate before further processing.

Make sure your blanks are aligned before manually moving them to the welding machine.