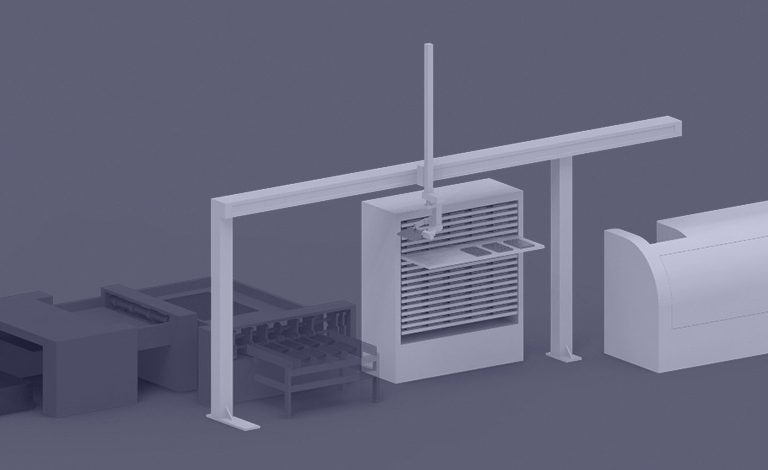

To equip a 3-piece canmaking line with an automatic blank feeder and “some buffer” is nothing new. New though, is the combination of Can Man’s PowerCUT™ (automatic high-performance slitter), the PowerFEED™ (a simplified and fast blank transfer system) and the industry’s largest, fully automated blank buffering system, the PowerSTORE™! New is therefore, that a canmaker can now use the production (up-) line practically nonstop, even with daily format changes!

How is that possible?

First of all, the PowerCUT™ allows a complete format change in only 45 minutes, even with multiple cutters on the first and second operation. Even more impressive is, that a height change is done in less than 15 minutes! The PowerCUT™ slitter is always faster than the welding line, and so is our PowerFEED™, the blank transfer system.

Due to the “greater than the line-capacity”, you are actually not fully utilizing those 2 systems. This led us to the idea to build a storage system, which is larger than what you’ve previously seen and can store an immense volume of blanks. With thePowerSTORE™, you have a buffer that allows you to continuously run your downline while doing any kind of changeovers on the slitter.

Quote of a customer who is already in use of our configuration:

Funny, that not every can manufacturer has recognized the huge advantage of this configuration yet.