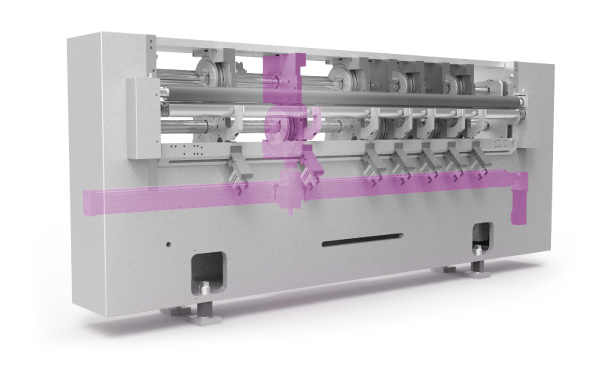

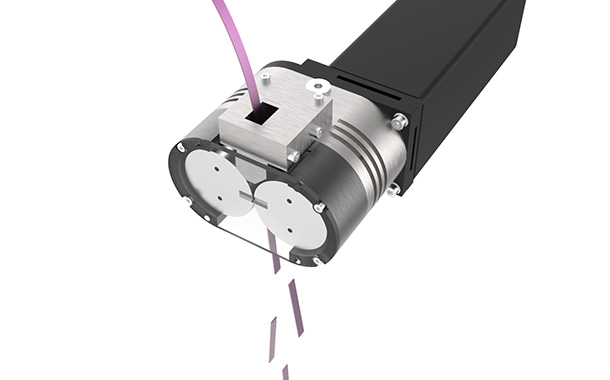

The newly developed large sized BIG 8 cutters which are integrated in super-precise housings are regrindable and allow a format change within only a few minutes.

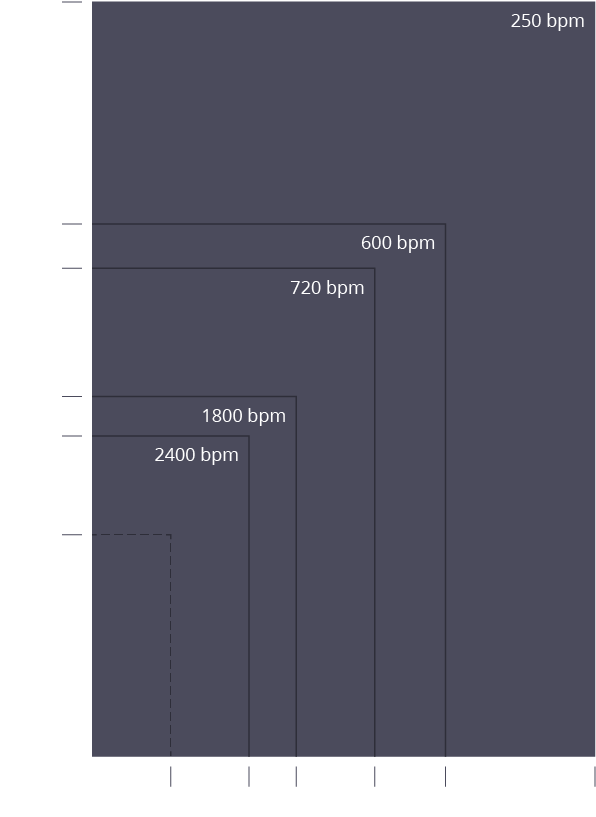

PowerCUT™ is now available in 3 “versions”. The “classic” – version whereas both cutting operations are executed by the precise, mechanical clamped MAWAG – cutters, the “flex” – version with a fast changeover for the height cut (2nd op) with the latest generation of our BIG8 monobloc cutting heads and now also as a “superflex” – version in which both operations are equipped with those fully automatised BIG8 cutting heads. watch the movie

A slitter needs speed, especially when operating as an independent unit, serving more than 1 canmaking line. Our newly designed table 2 is now able to run most sheet sizes at a speed of 40 sheets per minute!

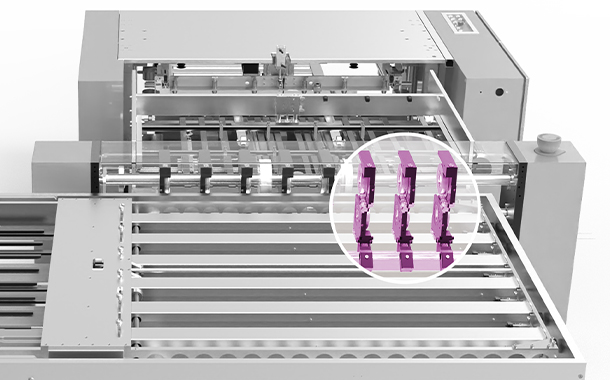

Nice side effect, no more dents in the, even thinnest and softest, material.

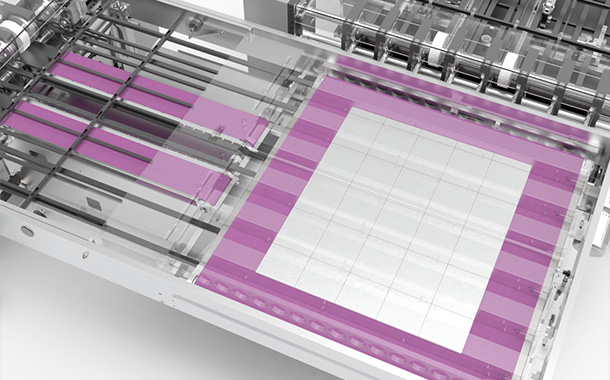

Higher speed and thinner material needs higher accuracy and brilliant surfaces. The sheets are constantly guided. Drop bars, step plates, infeed fingers and chaindogs are eliminated. Magnetic conveyors ensure smooth and safe sheet-, stripe- and blank- transport.

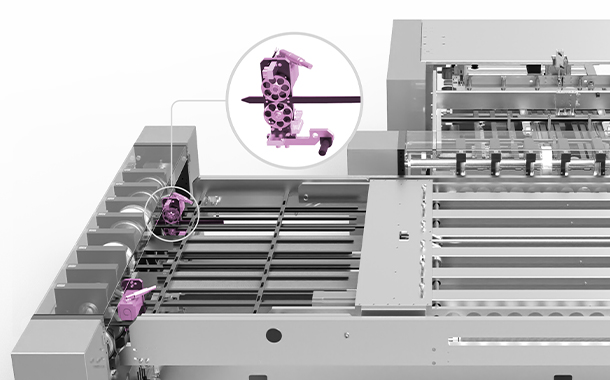

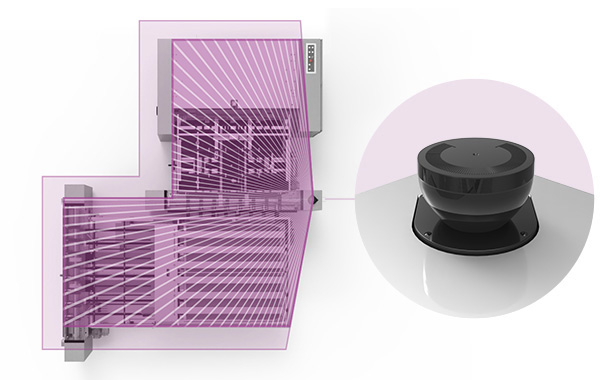

To avoid bulky covers we have included a reliable scanner safety device with two easy to setup scanning areas to trigger a warning (pause production) or emergency stop.

Complicated collecting and handling of trim strips is no longer necessary. Trim cutter‘s chop the trim strips to prevent jamming. After trimming the „left overs“ are very small and can be box collected or transferred into a container. A magnetic trim conveyor is optionally available.

| Production output | max. 40 sheets/min |

|---|---|

| Sheet sizes |

min. 550 x 550 mm max. 1200 x 1200 mm |

| Canbody height |

min. 50 mm with classic cutters min. (52) / 56 mm with BIG8 |

| Sheet thickness | 0.1 - 0.4 mm |

| Format change (excl. cutters) | 15 min |

| Cutter setting |

8 min / classic cutter pair 0 min / per BIG 8 automated |

| Format change SuperFLEX | 20 min, excl blank collector |

| Format change blank collector | 10 - 20 min, depending on no. of cutters |

| Electrical mains | 3 x 400 V + Ground, 50 / 60 Hz |

| Fuse & power | 3 x 25 A, 7 kVA |

| Air pressure & consumption | 6 bar, 10 m³/h |