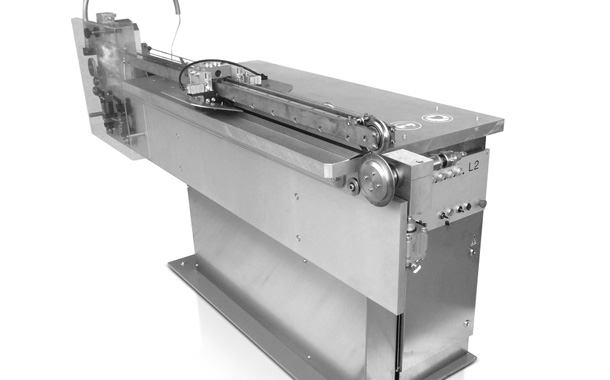

An upside down welding system enables the operator to weld the very heavy and big tubes comfortably. With a frequency controlled wire drive the speed can be optimized according to the to be welded product.

The machine construction itself as well as the mechanical components are stable and made of high quality materials. Long life upper and lower rollerhead with exchangeable welding ring lead to almost zero wear part costs.

| Diameter range | 100 - 1500 mm |

|---|---|

| Height / length range | 100 - 1500 mm |

| Material thickness | 0.3 - 1.25 mm |

| Sheet overlap | 6.0 mm |

| Production | Dep. on operator and length of products |

| Welding speed | 4 - 8 m/min |

| Copper wire diameter | 1.8 mm |

| Electrical mains | 3 x 400 VAC at 50 / 60 Hz + N + Ground |

| Fuse and power | 3 x 100 A, 50 kVA |

| Water pressure | 5 bar (absolute) |

| Flow rate / Pump capacity | min. 15 l/min |

| Cooling power | min. 6 kW |

| Cooling water temperature |

max. 15 °C with mercury - filled welding roll max. 20 °C with PowerROLL™ |

| Air pressure and consumption | 6 bar, 10 m³/h |

| Weldable materials | Tinplate, black steel, galvanized steel, stainless steel |