With up to 60 containers per minute the X5 is the fastest HVAC – welder available today.

With the automatic welder X5 – HVAC a machine has entered the market which can weld exceptional formats, sheet-thickness and materials, thanks to a solid frame-construction and a state of the art control.

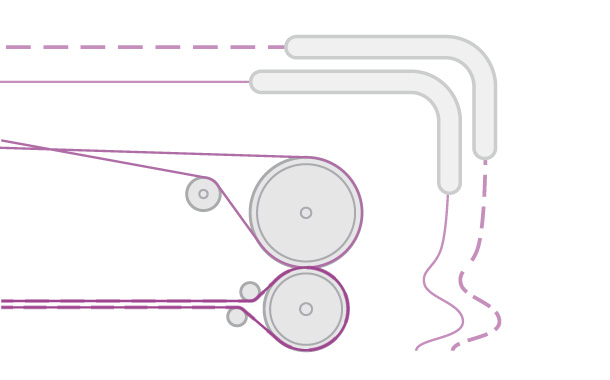

The connection-power is an important cost factor, especially when running heavy gauge, galvanized material. Thanks to optimized arrangement of the welding arms (PowerBAR) and the use of a frequency inverter (Pacemaker™), the electric power consumption of this welder is less than 30 Amps per phase at full load and maximum speed!

For most HVAC – applications and rather thin material, 1 copper wire will do the job. However the X5 – HVAC is equipped with all units to handle also 2 copper wires, which is required for heavy gauge material.

Threading 1 or 2 wires in is a “childs play” and only a selector switch has to “activate” the 2nd wire drive, which stands still when unused.

| Diameter range | 80 - 330 mm |

|---|---|

| Height range | 70 - 650 mm |

| Material thickness | 0.4 - 0.6 mm |

| Production output | up to 20 1/min |

| Format change | 30 minutes |

| Height change | 5 minutes |

| Welding speed | 4 - 20 m/min |

| Wire diameter | 2 x 2.0 mm |

| Electrical mains | 3 x 400 VAC + N + Ground, 50 / 60 Hz |

| Fuse and power | 3 x 32 A, 35 kVA |

| Water Pressure | 5 bar (absolute) |

| Flow rate | min. 40 l/min |

| Cooling power | min. 20 kW |

| Air pressure and consumption | 6 bar, 5 m³/h |