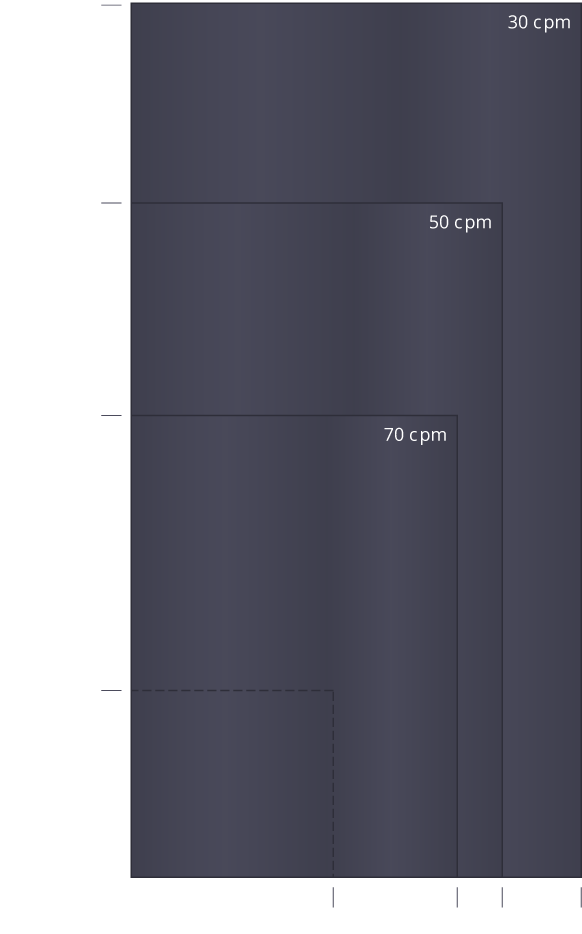

With up to 70 containers per minute, the X5 is the fastest large format welder available today.

The connection-power is an important cost factor, especially when running large containers. Thanks to an optimized arrangement of the welding arms (PowerBAR), the electric power consumption of X5 is less than 30 amps per phase at maximum welding power and speed.

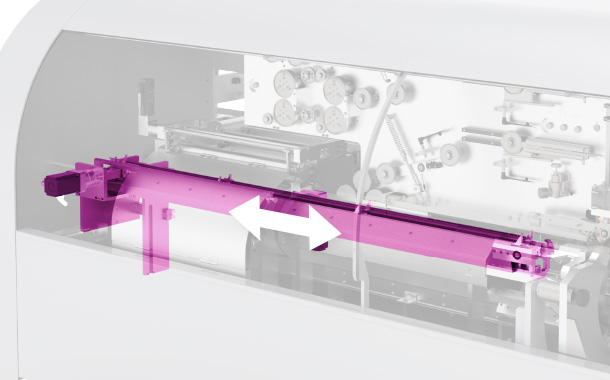

At the push of a button, the system correctly positions the feeder and can-body conveyor, adapts the speed of all servo drives, and sets the relevant welding parameters. These settings can be saved as recipes and loaded again via the intuitive HMI.

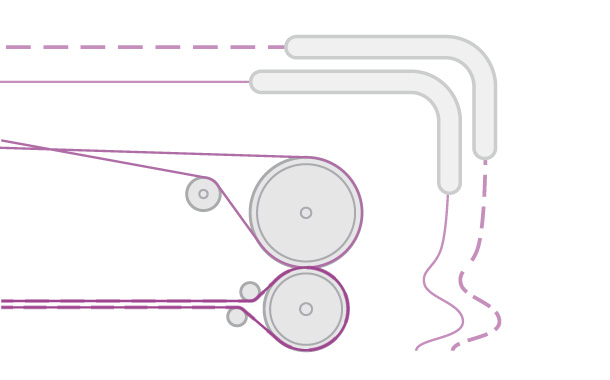

The rounded blanks are transported by means of 2 timing belts equipped with unibody connected pushfingers (patented). This unique transport-system, located inside the containers, guarantees no offset of the blank edges as well as height change within 5 minutes.

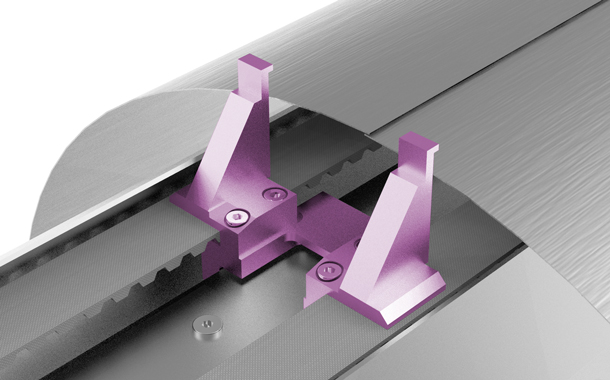

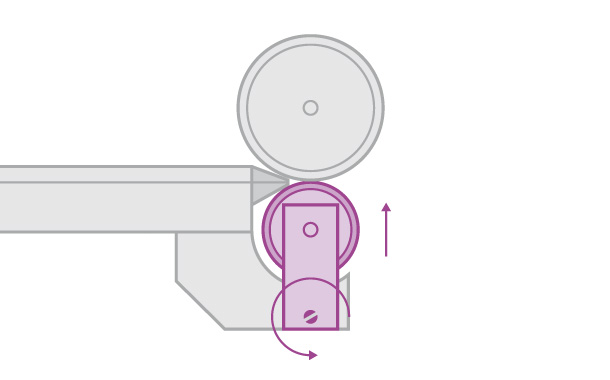

As a standard, only 1 instead of 4 items must be adjusted after redressing the welding roll to achieve a constant welding quality. That means minimal downtime and a reduction of human handling errors

A powerful I-PC (industrial PC) in combination with an advance software eliminates the limits of PLC’s (programmable logic controllers) and boots the handling and monitoring remarkably, worldwide wireless access included. The welder is operated over an easy to use and top reliable iPad operators panel. The software is structured so simple, it can really be operated intuitional.

For tinplate thicker than 0.36 mm, two copper wires are recommended to ensure top quality seams. A simple selector switch and extremely easy re-wiring let you choose between one or two wires.

| Diameter range | 180 - 400 mm |

|---|---|

| Height range | 120 / 150 - 650 mm |

| Blank thickness | 0.24 - 0.6 mm |

| Production output | up to 70 cpm |

| Welding speed | 10 - 32 m/min |

| Wire diameter | 2 x 1.5 or 1.8 mm |

| Format change | 30 minutes |

| Height change | 5 minutes |

| Electrical mains | 3 x 400 VAC + N + Ground, 50 / 60 Hz |

| Fuse and power | 3 x 40 A, 35 kVA |

| Water Pressure | 5 bar |

| Flow rate | min. 40 l/min |

| Cooling power | min. 20 kW |

| Air pressure and consumption | 5 bar, 42 m³/h |