The Pacemaker has the following options to connect the output of the weld power limiter to other systems/controls (i.e. can rejection control):

- E-Relay

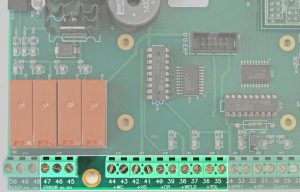

E-Relay of Pacemaker does stop the welder if weld power limiter is active. To connect, use the clamp No. 45, 46 and 47 (potential free relay contact 47=>com, 46=>nc, 45=>no).

To use this function, the parameter “Wld fault” in the Pacemaker settings has to be set to “E-Relay”. If weld power limiter is activated, the E-relay do switch on, welder stop and must be reset on the Pacemaker display before the welder can be restartet. Of course the operator has to check the last welded cans to make sure that no unwelded cans go to the downline.

- +Tol output (Clamp 35/36, 35=>0V, 36=>24Vdc)

This output is switching on if the weld power limiter is active and can be used also to activate an ejector or other function. The next can will be welded normally and +Tol output will switch off automatically. If you want to use that output, you can change the parameter “Wld fault” to “nothing”. In this case, the E-relay will not be activated and the welder can run continuously without to stop if the weld power limiter detect a can. Of course you need an additional logic for the eject timing and eject the right can.

- +CR output (Clamp 39/40, 39=>0V, 40=>24Vdc)

This output will be activated if the weld power limiter is active according to the parameter “WLD fault”. You can choose different settings like “CR39/40”, “CR 50ms”…

Example: CR 50ms => Pulse of 50ms on CR output if weld power limiter detect a bad can.

- Can Man eject unit

With this option it is possible to eject cans and also to eject the first and last can of a series. Please contact Can Man for an offer.Attention!!! +Tol and +CR output is supplied by the internal 24Vdc of the Pacemaker electronic board. This output is not potential free!!! Use a small 24Vdc relay to connect the signal with other systems/controls.The settings of beginning and end of can (T1/T2 or IT/ET) must be set correctly, also if you don’t use the IRED function. With this timing, the weld power do switch on the current for the next can after a stop in case of contamination (overlacquering).Code to enter the system setup: down, right, left, left, up, left, right, right