Problem:

Error message: “Jam canbody transport”

Possible Causes & Resolutions:

- Calibration crown: Possibly is adjusted too close (too much overlap). This can cause a high resistance. Readjust according manual.

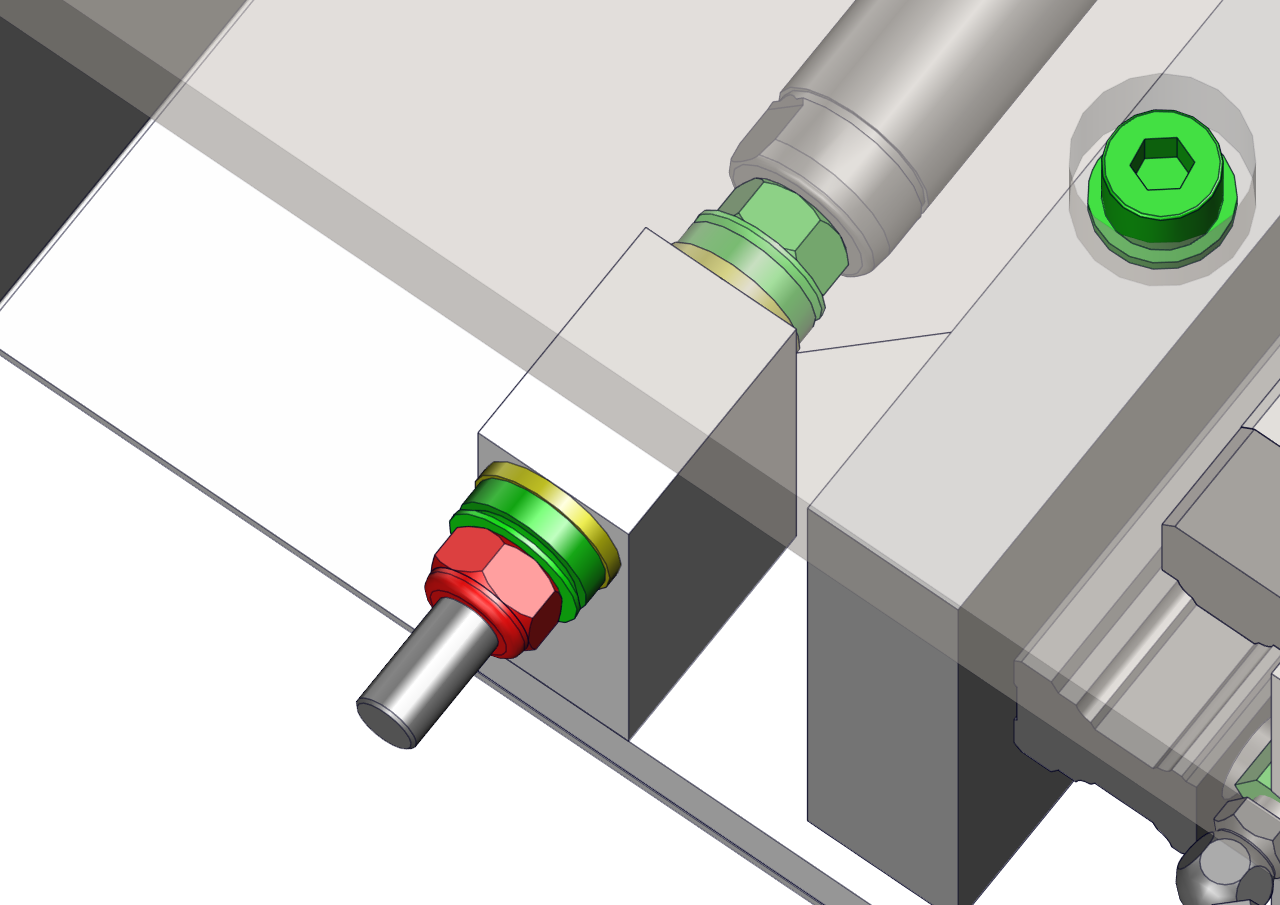

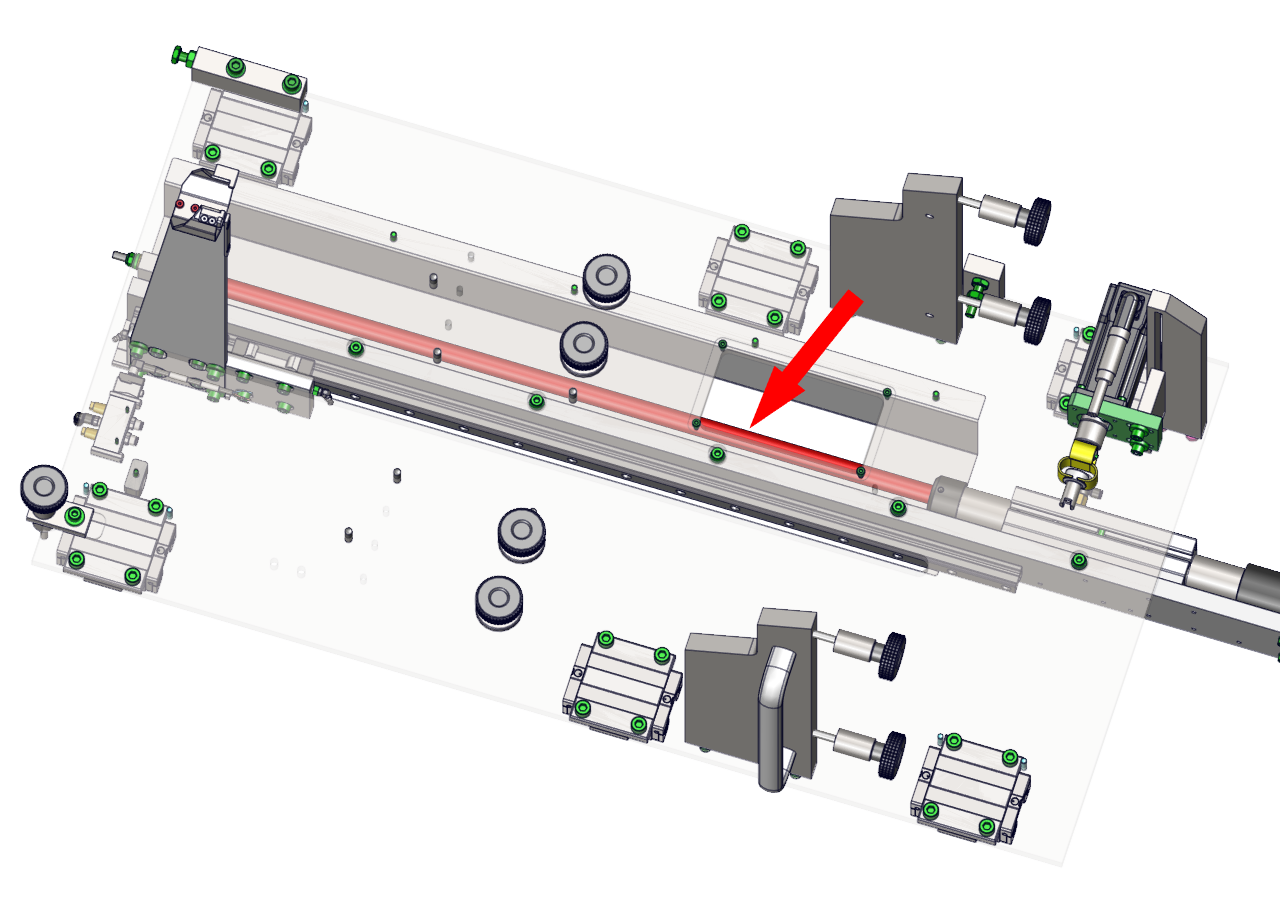

- Slider condition: Switch of machine and move the slider by hand. It must move smoothly. Since the slider of the linear motor contains strong magnets, remove dust or small metallic particles from the slider (see picture beside). To do this, remove the front cover.

- Wrong adjustment of curve time: Curve time means the duration for one complete move of linear motor. It must be shorter then one machine cycle! Example: Production speed => 120cpm => Machine cycle 500ms => curve time must be lower then 500ms.

- Enable signal of plc lost (Error message Linmot controller “User Err:Motion Cmd in Wrong St.“): Check wiring between PLC module and Linmot controller. Check PLC module. Clean the contact surfaces between the PLC modules with contact spray.

Additionally checkpoints for X8 with air cylinder downstacker

- Function of the valve Y1 for downstacker: Watch the LED on the valve for consitent timing / on – off switching. If inconsitent, please check output on PLC (Vipa output A4.6, Beckhoff output BA117 1/9), wiring and plug to valve or replace solenoid or entire valve.

- Cylinder condition: Possibly is worn, therefore check for are air leaks in both positions and to much backlash between piston rod and cylinder body. Removing air hoses (or air pressure) and move the piston in and out (up and down) manually.

NOTE: If you did remove the bracing, reassemble correctly. Check the insulation and tighten the self-locking nut only slightly, that the connection can adjust itself.