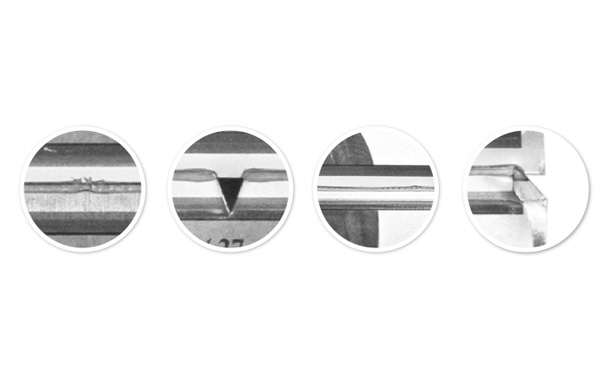

Common welding errors, such as overlacquering, bent corners, inconstant can gaps, „holes“ or cold / hot welds are detected by the most proven and latest measurement methods.

The system comes as a standard with an IR- (Infrared) and a G- (G-force or acceleration) – sensor. At 10 kHz each welding spot is “scanned” 10 times even at 1000 Hz welding frequency! Great advantage: both sensors are completely maintenance-free!

An advanced IPC manages the evaluation, comparison as well as the counting and rejecting of the faulty cans. The included development environment and complete code allows the integration of any type sensors and makes the system ready and compatible to coming developments.

This feature, together with the easy to use and understand HMI is essential for canmakers which are running various cansizes, materials or speeds. All the pre – settings required for the measurements, but also for the counting and the ejecting are done by the software. In fact all you have to do is to “teach” the system by the touch of 2 buttons and setting the limits for “good” or “bad” canbodies.

The installation of the Qualimaker2™ on a Can Man WeldCENTER™ can be executed in 2 days, also thanks to the absence of a time robbing welding arm removal and the sensitive wiring “through” the z – bar. Another 2 days will be required for start up, training and production monitoring.

| Welding speed | 20 - 100 m/min |

|---|---|

| Channels |

IR sensor (infrared) G sensor (acceleration) |

| Industrial PC | Beckhoff 1,9 GHz, 2 CORE, 2GB DDR 3 (as of 2014) |

| Software |

Microsoft Windows 7 Beckhoff TwinCAT |

| Communication | LAN-Modem and local W-LAN HotSpot integrated |

| Control | Apple iPad for internet-browser based user interface |

| Reject station | 2 light barriers + high speed pneumatic cylinder |