X8 WeldCENTER™ is the most compact welder in the market which provides easy, fast and safe operation because of smart empowering features. Lowest running costs because of the simple design that leads to less wear and tear. Highest quality in parts and service for reliable production.

A powerful I-PC (industrial PC) in combination with an advanced software eliminates the limits of PLC’s (programmable logic controllers) and boots the handling and monitoring remarkably, worldwide wireless access included. The welder is operated over an easy to use and top relyable iPad operators panel. The software is structured so simple, it can really be operated intuitional.

This compact static frequency inverter combines up to date digital processor technology for a very safe and easy to use operation with a remarkable power boost as a side effect. The unit is equipped to all fully automatic Can Man welders but can also be used to upgrade other types and brands of welders.

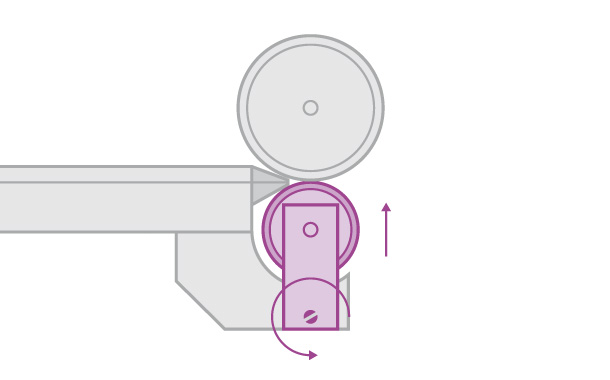

As a logical consequence of the Can Man idea for a fully automatic height change, changing the height with the X8 is a matter of seconds as the downstacker can be equipped with this feature. With an AC Linear Servo drive (patents pending), mechanical components (and wear parts!) are impressively minimized.

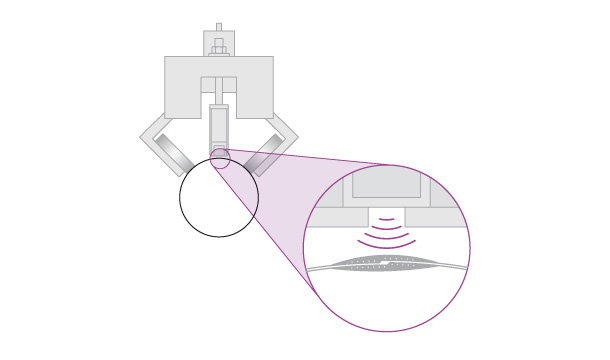

Another real breakthrough which is a standard on all Can Man welders is the “fixed welding plane”. With this feature, time consuming and difficult setting of the welding plane after regrooving the welding rollerheads becomes obsolete. No more hassles with pendulum rollerhead angles or finding the correct height of the calibration crowns, the z – bar tip (headpiece) or the exit conveyor. Adjust only what you‘ve changed!

The integration of the induction curing system PowerCURE™ leads to the most compact welder-curing-combination. Canbodies are transported scratchfree in hanging position on the V-shaped magnetic belts with no risk of damages of belts or coil due to a jam in the downline and the applied powder is cured within only 1 meter!

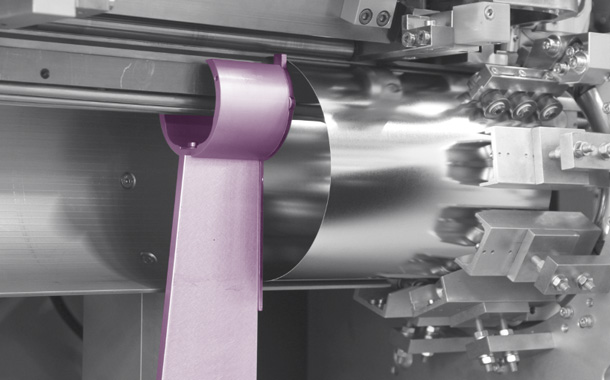

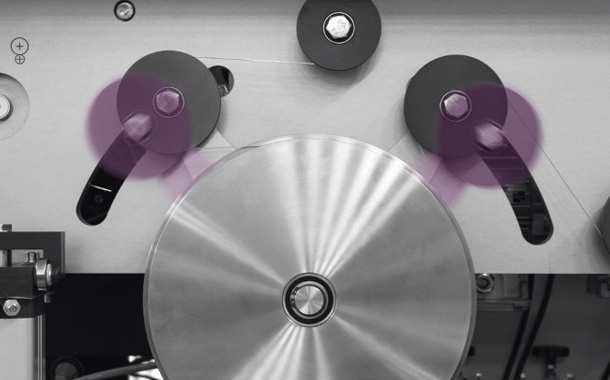

Our wire drive system does measure the speed of the wire through the tension in the wire loop. Therefore it is not necessary to finetune anything after regrooving and the wire can not break due to mishandling. An overlacquering control system does further protect the wire from breakage.

| Diameter range |

73 - 165 mm (nonstop downstacker) 99 - 330 mm (lifttable) |

|---|---|

| Height range |

50 - 360 (nonstop downstacker or lifttable) 50 - 420 / 540 (lifttable) |

| Blank thickness |

0.16 - 0.32 mm (nonstop downstacker) 0.19 / 0.22 - 0.38 mm (lifttable) |

| Seam overlap | min. 0.8 mm |

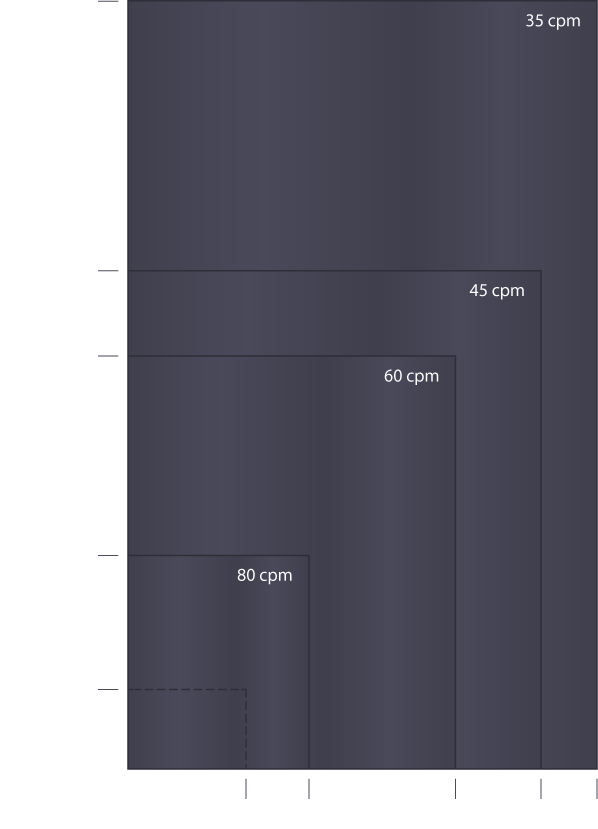

| Production output |

Max 120 cpm (nonstop downstacker) Max 80 cpm (lifttable) |

| Welding speed | 10 - 25 m/min |

| Wire diameter | min. 1.38 mm |

| Feeder |

Nonstop downstacker Lifttable feeding system |

| Format change | 20 minutes |

| Height change | 5 minutes |

| Electrical mains | 3 x 400 VAC + N + Ground, 50/60 Hz |

| Fuse and power | 3 x 32 A, 35 kVA |

| Water pressure | 5 bar (absolute) |

| Flow rate | min. 40 l/min |

| Cooling power | min. 10 kW |

| Air pressure & consumption | 5 bar, 42 m³/h |