Problem:

Circuit breaker Q5 trips when the machine is switched on or during production.

Possible Causes or Resolutions:

Problem:

Machine stops and message „Pacemaker: Profibus communication error“ is displayed.

Possible Causes & Resolutions:

The Pacemaker™ static welding inverter has a RAM battery for data retention and clock-buffering at power interruption/disconnection. The battery has a limited life span (about 5 years) that decreases especially without power supply (controller off). To prevent loss of data, the battery must be replaced early enough > ONLY BY AUTHORIZED AND SKILLED PERSONNEL!

To order a new battery please contact spares.canman@soudronic.com.

For instructions on how to replace the battery use the download link below. You will also find the correct order number there.

How to change the battery on a Pacemaker™ with integrated Qualimaker V1 electronic board:

Possible cause:

Corrective:

Possible cause:

Corrective measure:

Cause:

The actual value of the weld power limiter increases with the heating of the machine.

Corretive:

Readjust the weld power limiter, to a higher value. Observe the “Max” value from a “cold “ start to a “warm up” machine during production. See also note below.

Possible cause:

Download PDF english

Download PDF chinese

If the voltage value drops below 350 V the error message “Phase voltage error” shows up.

Check the main supply: L1 / L2 / L3.

Check also the input directly inside the PM.

QM board defect?

A reason for a voltage error could also be a defect on the QM board, which receives it’s supply from the elec. board of the PM.

To verify a defect you can remove the supply cable. The voltage value should go up around 20V (e.g. 375V to 395V), which is normal. If the increase much bigger than 20V the QM board has a defect and need to be replaced.

The voltage value on the touch screen is much lower than on the main terminal!

As a matter of fact, this electrical balancing of the two values has been done by CANMAN prior to the delivery. If there is a discrepancy you can adjust it.

You have to lose the small electronic board of Qualimaker (if applicable). This board is supplied by the big electronic board of PM. If you remove this supply cable, the voltage value goes up around 20V (e.g. 365V to 385V), which is normal.

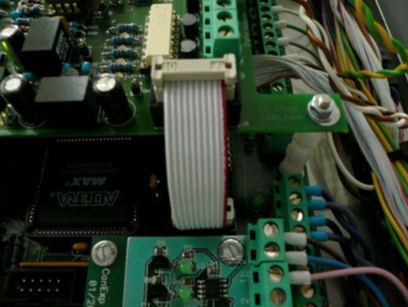

Now measure the input of terminals, for example 385V. Turn the small blue potentiometer (picture). Control the value on touch screen. Must be around 20V more than the measured value, if you have a QM board. If you have adjusted it, connect the supply of QM and now you have the correct value on touch screen.

NOTE:

Starting with the version of the V4 mainboard, the board has two potentiometers. You need to adjust the “UMains” potentiometer in this case.

FAQ – Trouble Shooting

Check the main supply

R-380VAC (L1), S-380VAC (L2), T-380VAC (L3).